Views: 8436 Author: Site Editor Publish Time: 2022-02-18 Origin: Site

Production MethodsEdit Broadcast

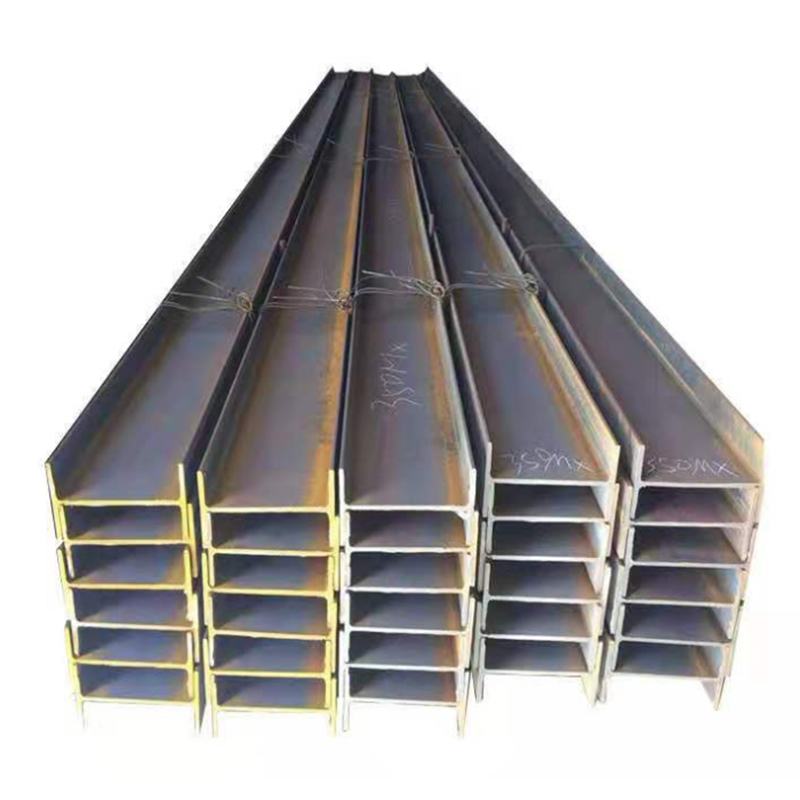

H-beam steel can be produced by welding or rolling. Welded H-beam is to cut strip of suitable thickness to suitable width, and weld the flange and web together on a continuous welding unit. Welded H-beam has the disadvantages of large metal consumption, difficult to ensure uniform product performance, and limited size specifications. Therefore, H-beams are mainly produced by rolling method. In modern steel rolling production, H-beams are rolled using universal rolling mills. The web of the H-beam is rolled between the upper and lower horizontal rolls, and the flanges are rolled and formed simultaneously between the side of the horizontal roll and the vertical roll. Since only the universal rolling mill cannot press down the flange edge, it is necessary to set an edge rolling machine behind the universal stand, commonly known as the edge rolling machine, in order to press down the flange edge and control the flange width. . In the actual rolling operation, the two stands are used as a group, and the rolling stock is reciprocated through several times (Fig. 2a), or the rolling stock is passed through several universal stands and one or two edger stands. The continuous rolling line consists of a certain reduction amount for each pass to roll the billet into a product of the required shape and size. At the flange part of the rolling piece, due to the sliding between the side of the horizontal roll and the rolling piece, the wear of the roll is relatively large. In order to ensure that the rolls can be restored to their original shape after heavy rolling, the sides of the upper and lower horizontal rolls of the roughing mill and the surfaces of the corresponding vertical rolls should be inclined at an angle of 3° to 8°. In order to correct the inclination angle of the finished flange, a finished universal rolling mill, also known as a universal finishing mill, is set up. The side of the horizontal roll is perpendicular to the axis of the horizontal roll or has a small inclination angle

Fudao Materials has an independent steel pipe factory, GI/PPGI factory, and hot-rolled steel plate processing factory.